Tutti i prodotti

-

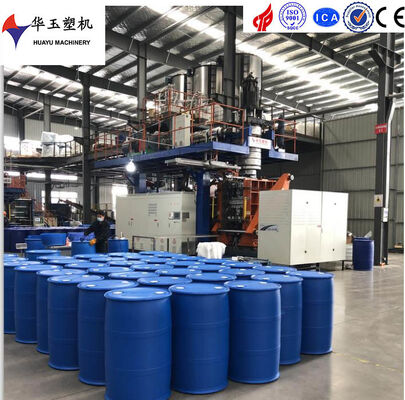

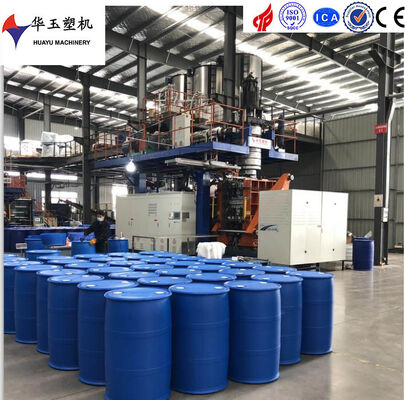

macchine di stampaggio a soffiatura a serbatoi ibc

-

Macchine di stampaggio a soffio a tamburo

-

macchine per lo stampaggio a soffio di serbatoi d'acqua

-

macchine per la stampatura a soffio di pallet

-

Macchina per lo stampaggio del kayak

-

Macchina per lo stampaggio a soffio di barriere stradali

-

Macchine per lo stampaggio a soffio galleggiante

-

Macchina per lo stampaggio su misura

-

Fabbricazione a sfogo

-

Macchina ausiliaria

220L Triple-Layer IBC Tank Blow Molding Machine with 20pcs/h Productivity

| Luogo di origine | Cina |

|---|---|

| Marca | HUAYU |

| Certificazione | ISO9001 CE |

| Numero di modello | HYBM-220L-3 |

| Quantità di ordine minimo | 1 INSIEME |

| Prezzo | 280000 USD |

| Imballaggi particolari | essere smontato in molte parti per il trasporto in container |

| Tempi di consegna | 4 mesi |

| Termini di pagamento | T/T, L/C |

| Capacità di alimentazione | 1 set 120 giorni |

Contattatemi per campioni e buoni.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

xDettagli

| Voltaggio | in corso | Potenza totale | 390KW |

|---|---|---|---|

| Potenza media | 180kW | Dimensione della macchina (L*W*H) | 7.5*5.5*6 |

| Produttività | 20 PCS/h | Diametro della vite | 90/100/90 mm |

| Rapporto L/D della vite | 30:1 | Capacità dell'accumulatore | 20kg |

| Diametro della matrice | Max 300mm | Dimensione massima dello stampo | 1200*1500mm (L*A) |

| Pressione massima dell'aria | 0,8 MPa | Consumo d'aria | 0,8×3(MPa × metro cubo al minuto) |

| Evidenziare | 220L IBC Tank Blow Molding Machine,Triple-Layer Blow Molding System,20pcs/h Drum Molding Machine |

||

Descrizione di prodotto

The Pinnacle of 220L Triple-Layer Drum Molding

Our 220L Triple-Layer Blow Molding System represents the culmination of engineering artistry and forward-thinking design, meticulously crafted for discerning manufacturers seeking superior performance and strategic value.

Distinguishing Attributes

Uncompromising Precision & Quality

Redefining industry benchmarks for consistency, our advanced co-extrusion technology and precision-engineered clamping unit produce drums with exceptional structural integrity and flawless finishes for superior performance and enhanced safety.

Redefined Productivity & Operational Excellence

Experience transformative efficiency with our AI-enhanced control center that orchestrates every cycle with precision, minimizing material waste while maximizing throughput. State-of-the-art hydraulic and electrical systems ensure peak performance with class-leading energy efficiency.

Fortified Durability & Dependability

Built for relentless heavy-duty operation using robust industrial-grade components and optimized frame design. This commitment to durability ensures exceptional longevity, minimal maintenance, and maximum uptime for your production line.

Visionary Design & Strategic Value

Engineered for seamless integration into smart factories, this system delivers compelling ROI by empowering manufacturers to outperform competitors, meet stringent market demands, and future-proof manufacturing capabilities.

Hydraulic System Specifications

| Main Oil Tank Capacity | 890L | Servo motor, less energy consumption, high efficiency, low noise |

| Main Oil Pump | Gear Pump 125CC | |

| Main Oil Pump Motor | 37kw | |

| Servo Oil Tank Capacity | 200L | |

| Servo Oil Pump Model | Plunger Pump 22 | |

| Servo Oil Pump Motor | 7.5kw |

Electronic System Specifications

| Main Operation Panel | Touch Screen 12" | |

| Control System | PLC | |

| Thickness Control Points | 200 Points |

Temperature Control: PLC Module - Advanced temperature regulation for precise manufacturing control.

Prodotti raccomandati